Pumping Chambers for Contaminated Water

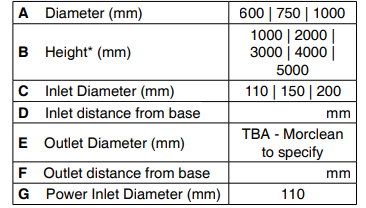

Our range of pumping chambers are ideal for pumping contaminated dirty water to foul drains, water to a surface drain or any process of outflow where levels and falls are insufficient for drainage via gravity, or where the outlet to drain is higher than the outlet. Our mini pumping chambers are constructed from GRP. They are available up to 5000mm deep and in 600mm, 750mm and 1000mm in diameter. For mini sump chambers over 600ml the top of the chamber is reduced to 600mm for added strength so that all the range, when installed, are neatly concealed under a standard cover and lid*.

Please note: This item requires frames and manhole covers

Specification and technical details are available on request.

All pumps are heavy duty stainless steel construction and fitted with integral level switches. The Morclean range of pumping chambers all are built as and when so that we can provide numerous site specific options including the pipe sizes, invert levels and pumping capacity. This is so that the chamber is specified exactly to the installation or a builders particular conditions.

Specification and technical details are available on request.

Our pumping chambers for contaminated water can be built with an additional failsafe or standby pump.

The main duty pump is backed up with a standby pump which is designed to activate in the case of a failure. The standby pump can then maintain the evacuation of contaminated or flood water until the fault can be discovered and fixed. During this time (though designed to site specific requirements) the chamber’s control panel will typically activate a warning light or beacon to indicate the failure.

*Covers and lids are an added extra. Pumping chambers are also all available above ground.

Please note: This item requires frames and manhole covers

The above requires manhole cover(s) and lid(s) (not included). Due to the weights involved covers and lids are expensive to transport and often cost more to ship than they are worth so we advise you source your own. You can purchase covers and lids from most builders merchants and below is a guide to assist you choosing the best type for the duty.

| Type | Size (mm) | Duty | European Standard | Loading | Typical Overground |

|---|---|---|---|---|---|

| Class A15 | 600 x 450 | Light | BS EN 124 | 3 tonne (approx) | Cars/Small Vans |

| Class B125 | Medium | 17 tonne (approx) | Cars/Small Commercial | ||

| Class D400 | Heavy | 38 tonne (approx) | Large Commercials/HGV |

About Pumping Chambers

(216Kb)

Pumping Chamber Spec Sheet

(249Kb)

The EA and SEPA Pollution Prevention Guidelines (PPG) which are jointly produced by the Environment Agency for England and Wales, the Scottish Environment Protection Agency, and the Environment and Heritage Service for Northern Ireland (Ref PPG3 / PPG13 / PPG4 / PPG 14) suggest that Class 2 wash bay silt traps and interceptors should be connected only to a mains foul drain, and Class 1 separators to surface drain.

The above assumes you have the consent to connect any outflow to a suitable drain as per the appropriate PPG Guideline. While we always endeavour to provide best advice and accurate information, it the responsibility of the client and/or landowner to comply with the law. Following any guideline doesn’t remove your responsibility to comply with the law and prevent pollution from your activities. Causing or allowing pollution is a criminal offence; compliance with any guidance isn’t a defence. You should make sure that the references to other sources of guidance are still current.

Extract from the Pollution Prevention Guidelines: PPG13

3. Requirements for all vehicle washing and cleaning activities

Activities that produce run-off from the vehicle onto the ground and use cleaning and valeting products should be carried out in areas that are clearly marked and isolated from surface water drainage systems, unmade ground and porous surfaces. These areas are called designated washing bays.

A designated washing bay should be designed so that run-off is:

- isolated using channels, gullies, gradient (fall on the surface) and kerbs

- directed to a silt trap or settlement tank to remove larger particles of silt and sediment

- either collected in a sealed system for reuse, discharged to the public foul sewer with prior permission

- of the local sewer provider or collected in a sealed system for authorised disposal

You should also:

- have procedures for everyone, including contractors, that cover where and how vehicle washing and cleaning should be carried out and what to do in a spillage emergency

- provide notices for designated washing bays saying what they’re for and that washing and cleaning should only be carried out in the bay

- consider whether a fence or barrier is required to prevent spray or wind drift out of the designated area

- have procedures and equipment which minimises water use and solid waste production

Extract from the Pollution Prevention Guidelines: PPG3

Closure devices and alarms

Closure devices

If too much oil is allowed to accumulate inside a separator, it will not work effectively and oil will escape. To avoid this, full retention separators must be provided with an automatic closure device that will prevent flow passing through the separator when the quantity of oil in the separator exceeds the oil storage volume (V).

Also, during emptying or maintenance the separator should be isolated to prevent the escape of waste oil. Open all isolation valves when the operation is complete.

Do not fit automatic closure devices to bypass separators unless they have been designed specifically to operate on such separators.

If the automatic closure device is activated the operator should be alerted by a high level alarm so that immediate maintenance can be carried out.

Automatic Warning Devices/Alarm systems

Separators must be provided with a robust device to provide visual and audible warning (if necessary to a remotely located supervisory point) when the level of oil reaches 90 per cent of the oil storage volume (V) under static liquid level conditions. This automatic warning device indicates that the separator is in need of immediate emptying for it to continue to work effectively.

Also, as the build up of silt will prevent the separator from working effectively, we recommend that you install a silt level alarm or another suitable device in your separator to alert you to the build-up of excessive levels of silt. In many cases, oil and silt alarms can be fitted to an existing separator. Silt alarms are most useful on those sites where high volumes of silt are likely to enter the separator, such as quarries, builder’s yards and major trunk roads.

Further equipment can be fitted to the separator, alongside a closure device and warning device, to alert the site operator to the routine maintenance requirements of the separator. This equipment might, for example, indicate when the next inspection is due and such ‘separator management systems’ will ensure that the separator continues to receive the appropriate level of attention.

Any electrical device used within a separator or used to monitor sensors placed within a separator must be intrinsically safe and certified to a suitable explosion protection standard. The location of the monitoring device, such as the alarm or ‘separator management system’ control panel, must be located within a safe area and conform to the requirements of BS EN 60079-10. For this reason it is important to always use qualified technicians who are familiar with the installation, calibration and servicing of intrinsically safe equipment. Regular maintenance and testing of equipment is essential.