Car Park Bypass Separators:

For Larger Hard Standing Areas and Roads

Class 1 and Class 2 Discharge

Car parks, hard standing areas and roads, although at relatively low risk from oil and petrol spillages do suffer from hydrocarbon contamination.

- Full treatment of flows of up to 6.5mm per hour rainfall

- Filters for Class 1

- Monitors normally fitted on both Class 1 and Class 2

- Class 2 improved cost savings with single shaft access

Pipework and Access Shafts

- Pipework inlets and outlets manufactured in virtually any size and orientation

- 100mm and 150mm uPVC used on standard sizes

- Larger sizes made from Glass Reinforced Plastic (GRP)

- Regulations require all Separators be vented: A standard Socket is provided in the access shaft.

- 1 metre extend cover as standard, any depth of installation catered for

PDF Downloads

Streamflow Models & Specifications

Click the PDF icon to view information about Streamflow models.

(67Kb)

Please note: This item requires frames and manhole covers

The above requires manhole cover(s) and lid(s) (not included). Due to the weights involved covers and lids are expensive to transport and often cost more to ship than they are worth so we advise you source your own. You can purchase covers and lids from most builders merchants and below is a guide to assist you choosing the best type for the duty.

| Type | Size (mm) | Duty | European Standard | Loading | Typical Overground |

|---|---|---|---|---|---|

| Class A15 | 600 x 450 | Light | BS EN 124 | 3 tonne (approx) | Cars/Small Vans |

| Class B125 | Medium | 17 tonne (approx) | Cars/Small Commercial | ||

| Class D400 | Heavy | 38 tonne (approx) | Large Commercials/HGV |

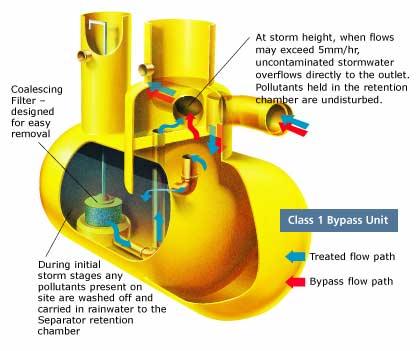

Bypass separators

Bypass separators fully treat all flows, for the area served, generated by rainfall rates of up to 6.5 mm/hour. This covers most rainfall events. Flows above this rate are allowed to bypass the separator. These separators are used when it is considered an acceptable risk not to provide full treatment for high flows, e.g. where only small spillages can occur and the risk of spillage is small such as on short stay car parks.

In cases where a large spillage might occur, it is not acceptable to use a by-pass separator. The only exception to this is a major trunk road where the size and type of spillage is impossible to foresee and the surface area drained makes it impractical to provide a full retention separator. For major trunk roads a SUDS approach incorporating a number of SUDS techniques is likely to be more appropriate.

On sites where high levels of silt are likely to enter the separator, the build up of silt must not be allowed to compromise the operation of either the separator or the by-pass device. On such sites (e.g. major trunk roads and quarries) an adequately sized silt separation chamber should be installed upstream of the separator and appropriate management systems put in place to monitor the situation and remove the silt when necessary. The use of SUDS techniques can minimise the amount of silt in the surface water run-off.

The EA and SEPA Pollution Prevention Guidelines (PPG) which are jointly produced by the Environment Agency for England and Wales, the Scottish Environment Protection Agency, and the Environment and Heritage Service for Northern Ireland (Ref PPG3 / PPG13 / PPG4 / PPG 14) suggest that Class 2 wash bay silt traps and interceptors should be connected only to a mains foul drain, and Class 1 separators to surface drain.

The above assumes you have the consent to connect any outflow to a suitable drain as per the appropriate PPG Guideline. While we always endeavour to provide best advice and accurate information, it the responsibility of the client and/or landowner to comply with the law. Following any guideline doesn’t remove your responsibility to comply with the law and prevent pollution from your activities. Causing or allowing pollution is a criminal offence; compliance with any guidance isn’t a defence. You should make sure that the references to other sources of guidance are still current.

Click below to view our full product guide. (opens in a new window)

Morclean’s quality administration systems have been assured and approved to the standards and guidelines of BS EN ISO 9000:2015 for the sales, service and hire of industrial cleaning equipment.

Our registration no. is 94/121120 and our standards and guidelines are externally audited by CIS.

- Please note that many models described on this website are bespoke, and as such cannot always be accurately depicted.

- All photographs and illustrations displayed on this website are representative of model ranges or a model series only. Individual models and specifications may vary from those shown.

- Please contact us if you require clarification or individual specifications of any equipment. Morclean reserve the right to update and amend the specification of our equipment and accessories without notice and in the interest of the customer.

- Images or specifications must not be reproduced with express written consent from Morclean Ltd.

- Any prices quoted are subject to VAT @ SR. E &OE